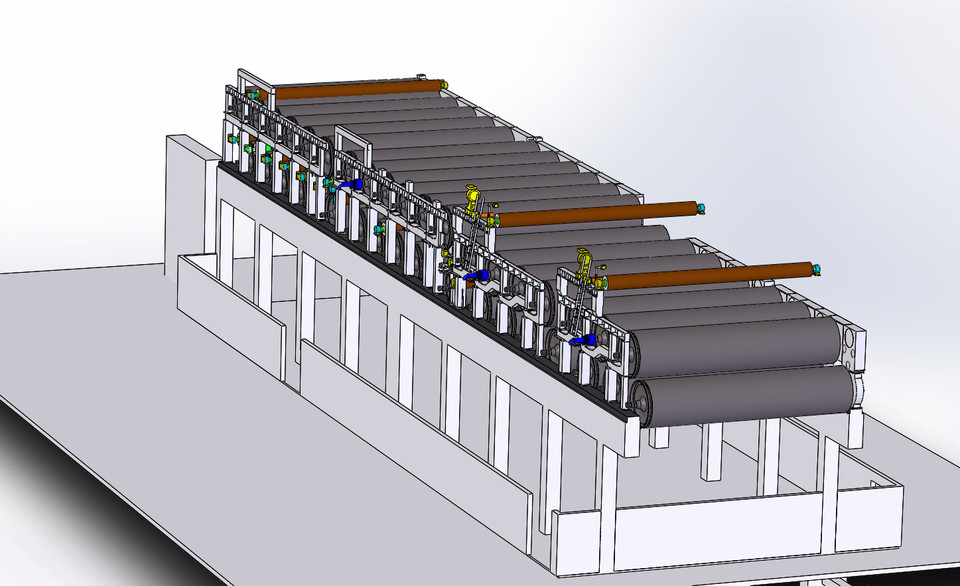

Paper M/C Rubber Rolls

Description

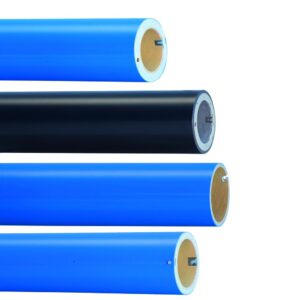

Rubber rolls are cylindrical tubes with a rubber covering or coating on their surface used in paper machines and other industries. They are a primary resource in paper mills and are used in every stage of production and processing. The rubber covering provides properties like traction, elasticity, and resistance to wear and tear, making them suitable for tasks such as material handling and printing presses.

Technical Specification

Rubber rollers used in paper machines can have a variety of technical specifications, including:

- Material: The roller can be made from natural rubber, nitrile rubber, silicone rubber, neoprene, or polyurethane

- Diameter: The roller can be 50–600 mm in diameter

- Length: The roller can be 0–3650 mm long

- Hardness: The roller can have a shore hardness of 45–65 shore “A“.

- Surface: The roller can have a wetting with rubber work nature

Application

Rubber rollers are used in many papermaking processes, including:

- Covering the pulp: The pulp is evenly spread on the roll

- Applying pressure: Other rollers apply pressure to the paper to help it solidify and evaporate moisture, and to maintain a uniform thickness

- Correcting, supporting, or adjusting: Rubber rollers can correct, support, or adjust paper webs and fabrics

- Introducing the paper or fabric: The wire guide roll can introduce the paper or fabric web into the wire

- Supporting and driving: The driving roller can support and drive, and can also adjust tension and perform control task

- Rubber rollers can be used in paper machines for a variety of applications, including:

- Newspaper printing, Commercial printing, Paper decorating, Embossing, Laminating, Banding, Suction pick-up, and Suction touch