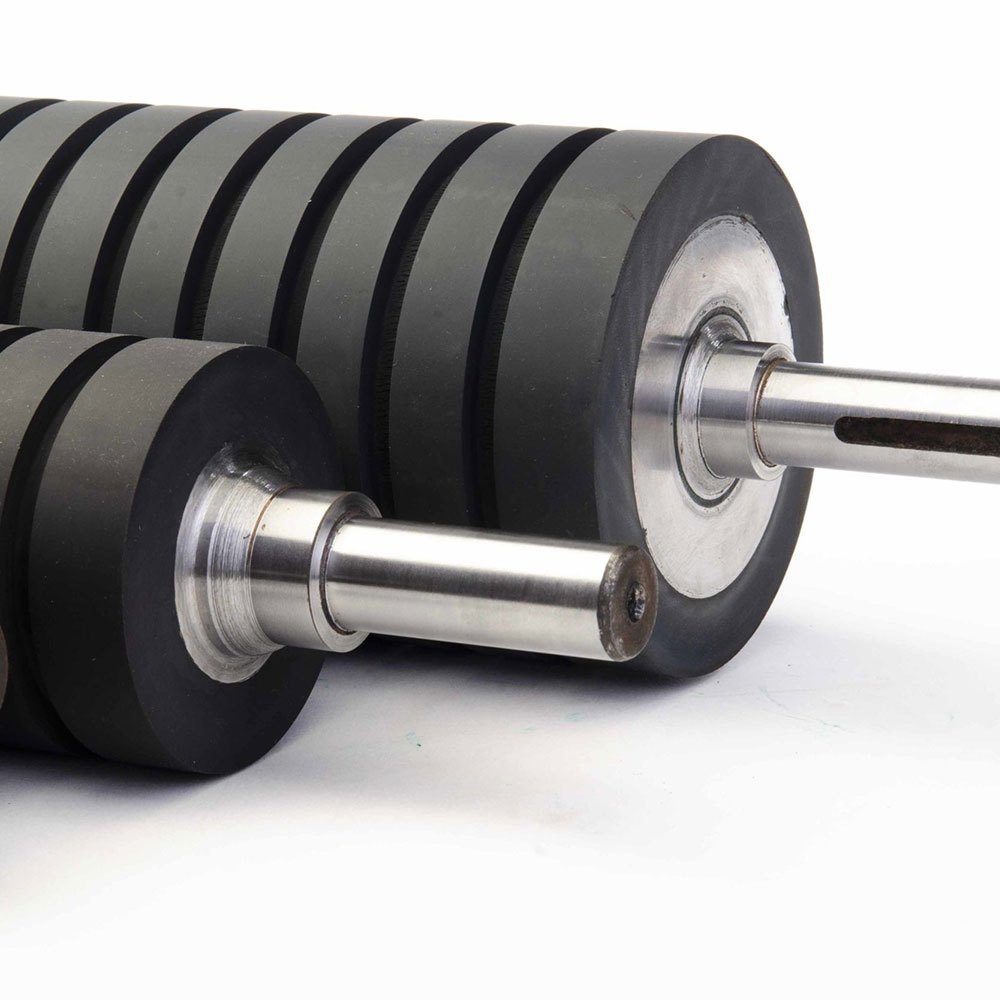

Sealing Cutting Rubber Rolls

Description

Our manufacturing process enables us to sell superior rubber rollers at the lowest price with high durability and less breakdown time. Our engineers follow a specific set of processes like it begins at designing then selecting right material & processes, temperature and pressure, grinding, finishing, polishing of rollers and the process ends at quality check. Furthermore, the quality of our rubber roller products and accessories meets all the international quality tests.

Rollers are a primary accessory for web process control. Even surface, appropriate material of the coating is done according to the application. Uniform hardness over the surface, along with precision workmanship plays a vital role in the performance of the roller.

Technical Specification

Technical specifications for sealing cutting machines can vary depending on the model and its intended use:

- Capacity: How many pieces or bags per hour or minute the machine can process

- Power: The machine’s voltage, phase, and power in kilowatts

- Dimensions: The machine’s length, width, and height in millimeters or feet

- Sealing width: The maximum width the machine can seal

- Cutting speed: How many strokes per minute the machine can make

- Material: The types of bags or films the machine can process, such as LD, LDPE, HM, PP, Eva, biodegradable, PVC shrink, or BOP

Application

This product used in many industries for effective bag sealing and cutting. This product uses double cutters that are ideal for making plain bags and T-shirt type bags.